Boost Yield: Percent Recovery Secrets Revealed! (60 Char)

Understanding percent recovery is crucial for optimizing processes in fields like analytical chemistry. The accuracy of measurements significantly impacts yield optimization. Specifically, percent recovery values reported by tools like Gas Chromatography-Mass Spectrometry (GC-MS) influence critical decision-making; higher values correspond to more reliable results. A deeper look at the best strategies for maximizing percent recovery is essential for those striving for greater process efficiency.

Image taken from the YouTube channel Kathryn Zimmermann , from the video titled Percent recovery calculation .

Imagine a pharmaceutical company racing to produce a life-saving drug. Every milligram counts, and even a slight increase in production efficiency can translate to thousands more patients treated. Or picture a research lab painstakingly synthesizing a novel compound; a marginal improvement in yield could unlock groundbreaking discoveries. These scenarios underscore the vital importance of percent recovery in achieving desired outcomes.

Percent recovery isn't just a number; it's a key performance indicator reflecting the efficiency of a chemical process. It quantifies how much of your desired product you actually obtain compared to the theoretical maximum possible. In essence, it's the yardstick by which we measure success in chemistry, pharmaceuticals, manufacturing, and beyond.

What is Percent Recovery? A Quick Definition

At its core, percent recovery is the ratio of the actual yield (the amount of product you obtain experimentally) to the theoretical yield (the amount of product you should obtain based on stoichiometry), expressed as a percentage.

A higher percent recovery indicates a more efficient process, signifying fewer losses and a more successful transformation.

The Ubiquitous Significance of Percent Recovery

Percent recovery plays a pivotal role across various scientific and industrial landscapes:

-

Chemistry: In chemical synthesis, optimizing percent recovery is crucial for obtaining sufficient quantities of a desired compound for research or further applications. It is paramount in reaction optimization.

-

Pharmaceuticals: Drug manufacturing demands high yields and stringent purity standards. Maximizing percent recovery directly impacts production costs, drug availability, and ultimately, patient health.

-

Manufacturing: In industrial chemical processes, even small improvements in percent recovery can result in significant cost savings and increased production output. This efficiency improvement will optimize overall profitability.

This article is your guide to unlocking the secrets of optimized percent recovery. We will delve into actionable strategies that will transform how you approach chemical processes. The focus will be on refining your experimental techniques, gaining a deep understanding of the influential parameters at play, and mastering the art of precise calculations. By implementing these strategies, you will be well-equipped to maximize your yield, minimize waste, and ultimately achieve enhanced outcomes in your work.

Understanding Percent Recovery: The Foundation for Optimization

As we've seen, the pursuit of higher percent recovery is central to successful outcomes in numerous fields. But before diving into specific techniques and strategies, it's crucial to solidify our understanding of the underlying principles. This section will dissect the percent recovery formula and explore the key factors that influence its value, laying the groundwork for effective optimization.

Defining Percent Recovery: A Quantitative Measure of Efficiency

At its heart, percent recovery is a simple yet powerful metric that expresses the efficiency of a process. It tells us what fraction of our desired product we actually managed to isolate from a given procedure.

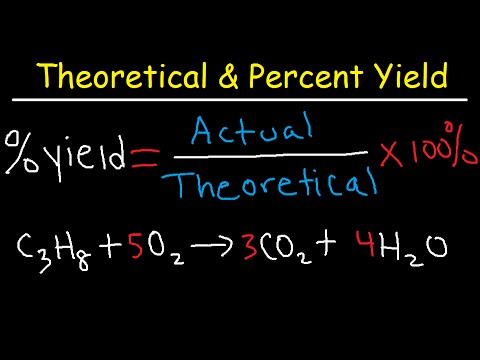

The Mathematical Formula

The mathematical representation of percent recovery is as follows:

Percent Recovery = (Actual Yield / Theoretical Yield) x 100%

Let's break down each component:

-

Actual Yield: This represents the experimentally obtained amount of your desired product after the completion of the process. It is crucial to report the correct unit of measurement (e.g., grams, moles). It reflects the reality of your lab work.

-

Theoretical Yield: This is the maximum possible amount of product that could be formed based on the stoichiometry of the reaction and the amount of limiting reactant used. This value is calculated and represents an ideal scenario.

Multiplying the ratio of actual yield to theoretical yield by 100% simply converts the result into a percentage, making it easier to interpret and compare results across different experiments.

Understanding what the formula represents is key to correctly calculating and interpreting your data.

Factors Affecting Percent Recovery: A Web of Interconnected Variables

Percent recovery isn't solely determined by the chemist's skill. It is influenced by a complex interplay of factors, ranging from the intrinsic properties of the chemical reaction to the quality of the starting materials and the proficiency of the person executing the procedure.

Chemical Reactions: Equilibrium, Kinetics, and Side Reactions

The very nature of the chemical reaction itself can significantly impact percent recovery.

-

Reaction Equilibrium: Many reactions are reversible, meaning they don't proceed to 100% completion. The equilibrium constant dictates the relative amounts of reactants and products at equilibrium, directly influencing the theoretical maximum yield.

-

Reaction Kinetics: Even if a reaction is thermodynamically favorable (i.e., has a large equilibrium constant), it might proceed very slowly. Insufficient reaction time can lead to incomplete conversion of reactants to products, resulting in a lower actual yield.

-

Side Reactions: Undesired reactions can occur alongside the main reaction, consuming reactants and forming byproducts. These side reactions reduce the amount of starting material available to form the desired product, lowering the overall percent recovery and purity.

Understanding these characteristics of a chemical reaction can help chemists modify certain parameters to promote increased yield in their reaction.

Starting Material Quality: Impurities and Degradation

The quality of the starting materials plays a crucial role.

-

Purity: Impurities in the starting materials can interfere with the reaction, leading to the formation of unwanted byproducts and a lower yield of the desired product.

-

Degradation: Starting materials can degrade over time due to exposure to air, light, or moisture. This degradation reduces the amount of active reactant available, lowering the theoretical yield and, consequently, the percent recovery.

Therefore, it's essential to use high-quality, pure starting materials and store them properly to prevent degradation.

Technique and Skill of the Analyst: The Human Element

Even with optimized reaction conditions and high-quality materials, the skill and technique of the analyst are paramount.

-

Proper Execution: Accurate measurements, careful transfers, and meticulous adherence to the experimental protocol are crucial for maximizing recovery. Seemingly minor deviations can introduce significant losses.

-

Attention to Detail: Paying close attention to details such as temperature control, mixing efficiency, and proper use of equipment can significantly impact the yield and purity of the final product.

The experimenter's attention and experience are essential to maintaining the best possible recovery rates.

By understanding these fundamental factors, we can begin to develop strategies to optimize percent recovery and maximize our chances of success in the lab or the manufacturing plant. The next step is to identify techniques for optimizing yield in processes, such as extraction and isolation.

Optimizing Recovery During Extraction and Isolation: Refining Your Techniques

Having established a solid foundation in the principles of percent recovery, it’s time to translate this knowledge into practical strategies. The heart of maximizing yield often lies in the execution of separation and purification techniques. This section dives into specific methods like extraction, distillation, and recrystallization, offering insights on how to fine-tune your approach for optimal results.

Extraction Techniques

Extraction is a cornerstone of many chemical processes, allowing for the selective isolation of a desired compound from a mixture. The efficiency of an extraction hinges on several key factors, each requiring careful consideration.

Solvent Selection: The Key to Selective Extraction

Choosing the right solvent is paramount for successful extraction. Several properties come into play:

-

Polarity: "Like dissolves like" is a guiding principle. Match the solvent polarity to that of your target compound.

Polar solvents (e.g., water, alcohols) dissolve polar compounds, while nonpolar solvents (e.g., hexane, diethyl ether) dissolve nonpolar compounds.

-

Boiling Point: A low boiling point solvent is generally preferred for easier removal after extraction.

However, consider the potential for evaporation losses during the extraction process itself.

-

Selectivity: The ideal solvent selectively dissolves your target compound, leaving impurities behind.

This minimizes the need for further purification steps.

Optimizing Extraction Parameters: Time, Temperature, and Solvent Ratios

Beyond solvent selection, optimizing these parameters can significantly boost recovery:

-

Time: Ensure sufficient contact time between the solvent and the mixture to allow for complete transfer of the target compound.

However, prolonged extraction can also lead to the extraction of unwanted impurities.

-

Temperature: Increasing the temperature can sometimes enhance the solubility of the target compound and accelerate the extraction process.

But be mindful of potential degradation at higher temperatures.

-

Solvent Ratios: Multiple extractions with smaller volumes of solvent are generally more efficient than a single extraction with a large volume.

Experiment with different solvent-to-mixture ratios to find the optimal balance.

Distillation Strategies

Distillation is a powerful technique for separating liquids based on differences in their boiling points. Choosing the right distillation method and carefully controlling distillation parameters are critical for maximizing recovery.

Fractional vs. Simple Distillation: Choosing the Right Tool

-

Simple Distillation: Suitable for separating liquids with significantly different boiling points (typically >80°C difference). It is best for removing a volatile solvent from a non-volatile product.

-

Fractional Distillation: Used when the boiling points of the liquids are closer together.

The fractionating column provides a larger surface area for repeated vaporization and condensation, leading to better separation.

Choose fractional distillation when separating two or more volatile liquids.

Optimizing Reflux Ratio and Temperature Control

-

Reflux Ratio: The ratio of condensate that is returned to the distillation column versus the amount that is collected as distillate.

A higher reflux ratio leads to better separation but also takes longer. Optimize this balance.

-

Temperature Control: Slow, careful heating is essential for achieving good separation.

Monitor the temperature closely and adjust the heating rate to maintain a steady distillation rate.

Avoid sudden temperature spikes, which can lead to carryover of unwanted compounds.

Recrystallization Methods

Recrystallization is a purification technique that relies on differences in solubility to separate a desired compound from impurities. Careful solvent selection and controlled cooling are key to achieving high recovery and purity.

Solvent Selection for Effective Impurity Removal

The ideal recrystallization solvent should:

- Dissolve the compound at high temperatures but not at low temperatures.

- Dissolve impurities readily at all temperatures, or not dissolve them at all.

- Be easily removable from the purified crystals (e.g., low boiling point).

Controlling Cooling Rates for Optimal Crystal Structures

-

Slow Cooling: Generally promotes the formation of large, well-formed crystals with fewer impurities.

This allows for a more efficient exclusion of impurities from the crystal lattice.

-

Rapid Cooling: Can lead to the formation of small, less pure crystals.

Control the cooling rate carefully to maximize both yield and purity. Seeding can also help the formation of pure crystal structures.

Having dedicated effort to extracting and isolating your desired product, the focus now shifts to preservation. Minimizing loss and maximizing purity are crucial steps to ensuring that the gains made during separation aren't diminished in the final stages.

Minimizing Loss and Maximizing Purity: Preserving Your Product

The journey to a high percent recovery doesn't end with extraction and isolation. Often, the most insidious losses occur in the seemingly mundane steps that follow. Mastering the art of product preservation involves identifying potential pitfalls and implementing strategies to safeguard your hard-earned yield. Furthermore, the relationship between purity and yield is often a balancing act. A product of extremely high purity might come at the cost of a lower yield and vice versa.

Identifying Sources of Loss

Loss can occur at any stage of a chemical process. Identifying where these losses happen is the first step towards preventing them.

Transfers Between Vessels: The Invisible Thief

Each transfer of material from one container to another presents an opportunity for loss. Even small amounts left behind in flasks, beakers, or filtration apparatus can add up, significantly reducing your final yield. This is often overlooked.

Quantitative transfer, the technique of ensuring all material is transferred from one vessel to another, is thus paramount. It involves techniques like rinsing the original container multiple times with a suitable solvent and carefully transferring all rinsings.

Incomplete Reactions: A Missed Opportunity

A reaction that doesn't proceed to completion leaves unreacted starting material and possibly unwanted byproducts. This directly impacts the amount of desired product you can ultimately isolate.

Ensuring reactions proceed to completion often requires careful attention to reaction conditions such as:

- Reaction Time

- Temperature

- Catalyst Activity

- Stoichiometry

Side Reactions and Degradation Pathways: The Unintended Consequences

Chemical reactions rarely follow a single, clean path. Side reactions can consume your starting material, leading to the formation of unwanted byproducts and reducing the yield of your target compound.

Similarly, degradation pathways can break down your product, especially if it's sensitive to light, air, or moisture. Understanding potential side reactions and degradation mechanisms is crucial for choosing appropriate reaction conditions and storage methods.

Strategies to Minimize Loss

Once you've identified the potential sources of loss, you can implement specific strategies to mitigate them.

Mastering Quantitative Transfer Techniques

As previously mentioned, quantitative transfer is essential. This involves:

- Using a suitable solvent to rinse the original container multiple times.

- Using a glass stirring rod to dislodge any remaining solid material.

- Ensuring all rinsings are transferred completely.

- Using a funnel to avoid spills.

These seemingly small actions can collectively lead to a noticeable increase in yield.

Optimizing Reaction Conditions to Minimize Side Reactions

Careful control over reaction conditions can significantly suppress side reactions. This might involve:

- Adjusting the reaction temperature.

- Using a different catalyst.

- Adding a scavenger to trap unwanted byproducts.

- Modifying the stoichiometry of the reactants.

Thoroughly researching the reaction mechanism and potential side reactions is critical for identifying the optimal conditions.

Utilizing Appropriate Drying Agents and Handling Techniques

Water is a common enemy in chemical processes. It can interfere with reactions, degrade products, and complicate purification. Using appropriate drying agents like magnesium sulfate or sodium sulfate is crucial for removing residual water from organic solutions.

Proper handling techniques are equally important. This includes:

- Storing materials in airtight containers.

- Protecting light-sensitive compounds from exposure.

- Working under an inert atmosphere when necessary.

Understanding and Assessing Purity

Yield without purity is often meaningless. A high yield of an impure product might be less valuable than a lower yield of a highly pure one.

The Intricate Relationship Between Purity and Yield

Purity and yield are often inversely related. Attempts to maximize purity through rigorous purification steps can lead to losses of the desired product, reducing the overall yield. Conversely, prioritizing yield without sufficient purification can result in a product contaminated with impurities. Finding the right balance between purity and yield is therefore a key challenge. The acceptability of this balance depends on the downstream application of the compound.

Techniques for Assessing Purity

Several analytical techniques can be used to assess the purity of a compound. These include:

- Melting Point Determination: A sharp melting point range is indicative of high purity.

- Thin Layer Chromatography (TLC): TLC can reveal the presence of impurities as additional spots on the TLC plate.

- Spectroscopic Methods (NMR, IR): These techniques can identify the presence of specific impurities based on their characteristic spectral signatures.

While a full discussion of these techniques is beyond the scope of this section, it's important to remember that assessing purity is an essential step in determining the overall success of a chemical process.

Having dedicated effort to extracting and isolating your desired product, the focus now shifts to preservation. Minimizing loss and maximizing purity are crucial steps to ensuring that the gains made during separation aren't diminished in the final stages. With your carefully purified product now in hand, understanding the journey’s overall efficiency becomes paramount. This is where the accurate calculation and interpretation of percent recovery take center stage, providing invaluable insights into your process and guiding future optimizations.

Calculating and Interpreting Percent Recovery: Ensuring Accuracy

Percent recovery isn't just a number; it's a key performance indicator reflecting the effectiveness of your experimental procedure. It quantifies how much of your desired product you successfully obtained relative to the maximum possible yield. Accurate calculation and thoughtful interpretation of this value are essential for evaluating your work, identifying areas for improvement, and ensuring the reliability of your results.

Accurately Determining Theoretical Yield

The theoretical yield represents the maximum amount of product you could obtain if everything went perfectly, based on the stoichiometry of the balanced chemical reaction. It's the ideal, unachievable in practice but crucial for comparison.

Using Stoichiometry and Balanced Chemical Reactions

The foundation of calculating theoretical yield lies in a correctly balanced chemical equation. This equation provides the molar ratios between reactants and products. From this, and knowing the amount of your limiting reagent, you can calculate the maximum possible moles of product formed.

Remember to convert all masses to moles using the appropriate molecular weights before performing any calculations. This step is critical for accurate stoichiometric analysis.

Accounting for Limiting Reagents in the Calculation

In most reactions, one reactant will be completely consumed before the others. This is the limiting reagent, as it dictates the maximum amount of product that can be formed. Identify the limiting reagent carefully; an error here will propagate through the entire calculation.

The theoretical yield is always based on the number of moles of the limiting reagent.

Precisely Measuring Actual Yield

The actual yield is the amount of product you actually obtain after performing the experiment and isolating your product. Obtaining an accurate actual yield is paramount to determining an accurate percent recovery.

Proper Drying and Weighing Techniques for Consistent Results

Accurate weighing is non-negotiable. Use a calibrated balance and handle your product with care to avoid any loss or contamination. More subtly, ensuring your product is completely dry before weighing is crucial.

Residual solvent or moisture can significantly inflate the apparent yield, leading to a misleadingly high (and inaccurate) percent recovery. Dry your product thoroughly using appropriate methods like a vacuum oven or desiccator.

Accounting for Residual Solvents or Moisture Content

Even with careful drying, trace amounts of solvent or moisture may persist. If highly accurate results are needed, consider techniques like Karl Fischer titration to quantify the water content, or spectroscopic methods to check for residual solvents.

Correct your measured mass accordingly to reflect the pure product yield. This extra step can significantly improve the accuracy of your percent recovery calculation.

Interpreting Percent Recovery Results

Once you have both the theoretical and actual yields, calculating the percent recovery is straightforward: (Actual Yield / Theoretical Yield) x 100%. But what does that number actually mean?

Understanding What a "Good" or "Bad" Recovery Means in a Given Context

There's no universal "good" percent recovery. What's acceptable depends heavily on the complexity of the reaction, the scale of the experiment, and the nature of the product. Multistep syntheses will naturally have lower overall recoveries than simple reactions.

A recovery of 90% might be excellent for a difficult reaction, while 50% might be disappointing for a routine transformation. Context is everything.

Troubleshooting Low Recovery Values Through Investigation

A low percent recovery signals a problem somewhere in your procedure. The key is to systematically investigate potential sources of loss.

Consider these questions:

- Was the reaction complete?

- Were there significant side reactions?

- Were there any losses during transfers or purifications?

- Was the product fully recovered from the drying agent?

By carefully reviewing each step, you can identify the most likely cause and implement corrective measures for future experiments.

Importance of Accurate Record Keeping

Finally, none of these strategies matter if they aren't accompanied by meticulous record-keeping.

Maintaining detailed notes and logs for traceability and analysis is essential.

Document everything: reaction conditions, reagent sources, purification methods, drying times, and all measured weights. This documentation will allow you to trace back any errors, troubleshoot low recoveries, and optimize your procedure for future success. Record keeping provides an invaluable resource for future investigations and reference.

Video: Boost Yield: Percent Recovery Secrets Revealed! (60 Char)

FAQs: Boost Yield - Percent Recovery Secrets

Here are some frequently asked questions to clarify the key concepts discussed regarding boosting yield and maximizing percent recovery.

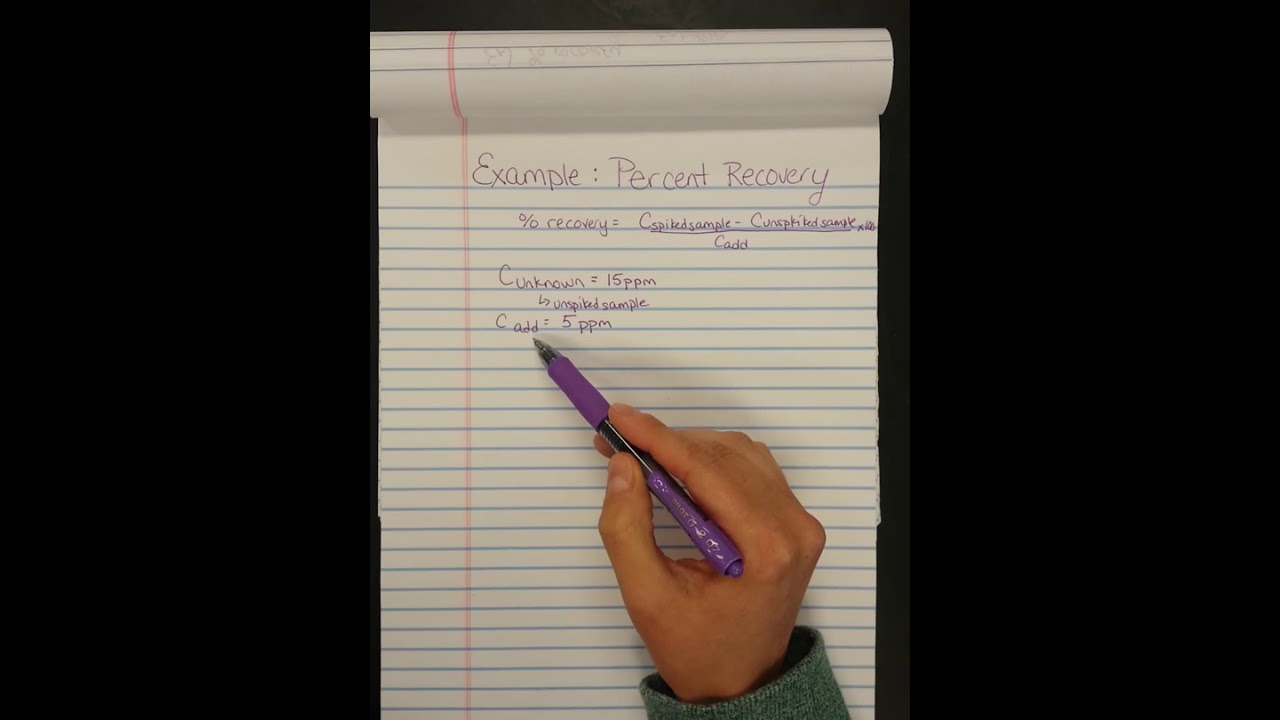

What exactly does "percent recovery" mean in this context?

Percent recovery refers to the percentage of the desired substance that you successfully extract or isolate from the initial source material. A higher percent recovery means you're losing less of your target compound during the process. Improving percent recovery is crucial for maximizing yield.

Why is knowing the percent recovery so important?

Knowing your percent recovery allows you to optimize your extraction or isolation methods. If your percent recovery is low, you know there's room for improvement in your techniques, solvent choices, or other process parameters. It's a key metric for efficiency.

How can I accurately measure percent recovery?

You need to quantify both the amount of your target compound present in the starting material and the amount you successfully recover after the extraction/isolation process. Analytical techniques like chromatography (HPLC, GC) or spectroscopy (NMR, UV-Vis) are often used. Calculating the ratio will give you the percent recovery.

What factors can significantly impact percent recovery?

Several factors can affect percent recovery including the choice of solvent, temperature, extraction time, pH, and the effectiveness of any purification steps. Paying close attention to these variables and optimizing them is essential for achieving a high percent recovery and, thus, a better yield.